RV-150

RAY ATTACHMENTS

| Availability: | |

|---|---|

| Model | Unit | RV-100 | RV-150 | RV-250 | RV-280 | RV-300 | RV-330 | RV-350 | RV-400 |

| Vibration Frequency | rpm | 2500 | 2500 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure | Mpa | 30 | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force | kn | 117 | 172 | 265 | 335 | 350 | 372 | 455 | 485 |

| Max. Pile Length | Standard(m) | 4 | 5 | 7 | 7 | 7 | 8 | 8 | 8 |

| Cylinder down(m) | 6 | 8 | 9 | 9 | 9 | 10 | 10 | 10 | |

| Extension arm(m) | / | / | 12 | 12 | 13 | 15 | 18 | 18 | |

| Arm Weight | kg | 160 | 260 | 500 | 500 | 670 | 670 | 750 | 750 |

| Arm Size | mm | 1242*300*710 | 1800*300*750 | 2600*500*900 | 2600*500*900 | 2650*600*900 | 2650*600*900 | 2700*500*940 | 2700*500*940 |

| Hammer Size | mm | 1160*960*1003 | 1210*1050*1120 | 1500*1110*1400 | 1500*1300*1500 | 1750*1450*1350 | 1750*1450*1350 | 1850*1600*1550 | 1850*1600*1550 |

| Hammer Weight | kg | 850 | 1100 | 1700 | 1900 | 2100 | 2300 | 2600 | 2700 |

| Excavator | T | 7-12 | 12-17 | 20-25 | 25-30 | 30-33 | 33-38 | 38-45 | 45-52 |

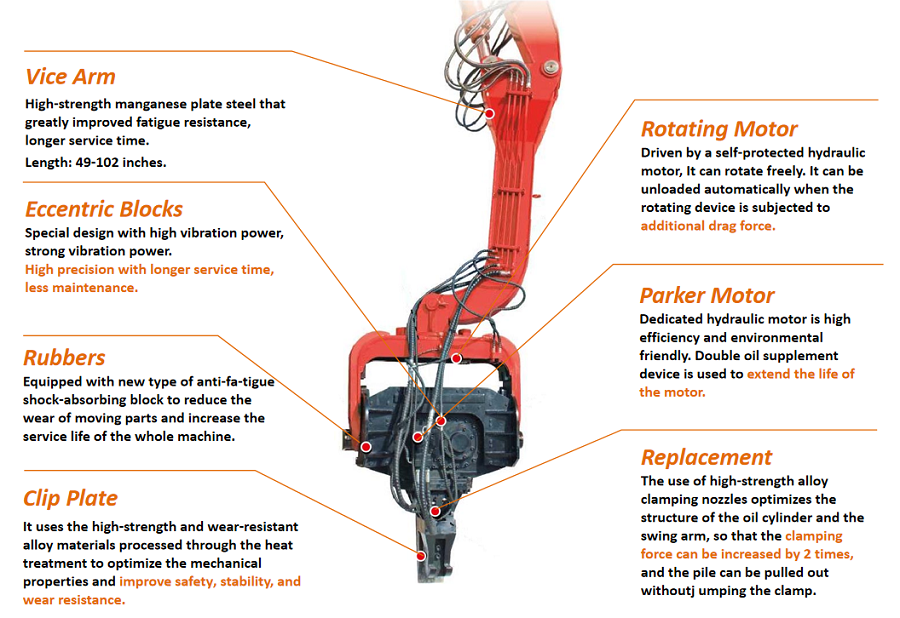

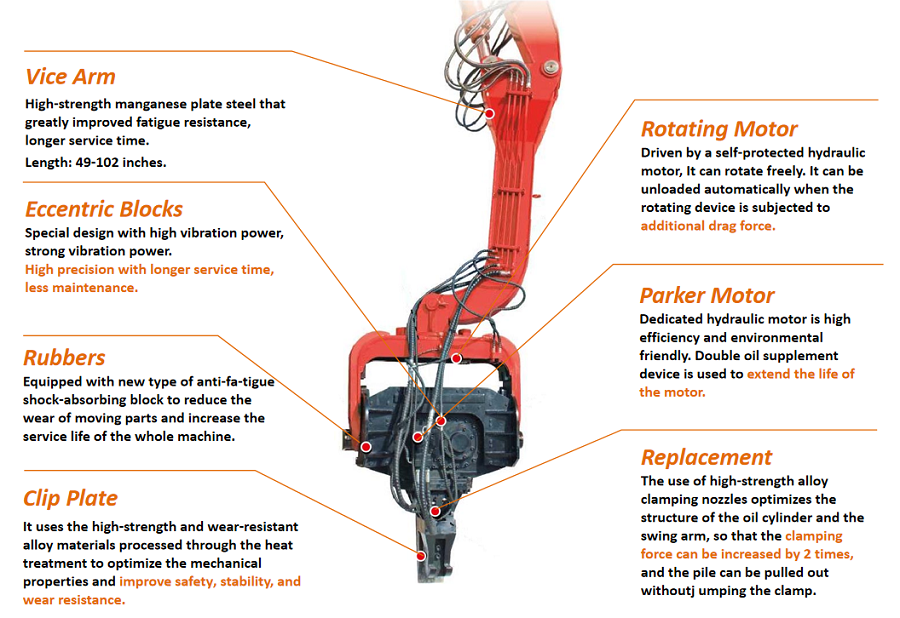

1. High efficiency: the speed of vibration pile sinking and pulling is 4-7m/min, and the fastest is 12m/min( in non-silty soil).

2. Multiple functions: Except for various piles, it can also build thin-wall anti-seepage walls, deep compaction treatment, ground compaction treatment, and other special constructions.

3. Environmental protection: lower noise, no pollution, high-frequency hydraulic pile drivers can fully meet the environmental protection requirements.

4. Wide range of functions: Suitable for any shape and material: steel pipe piles and concrete pipe piles, wood piles, etc.

RAY Vibro hammer is a machine used to drive piles in/out of the ground for constructing structures like bridges, harbors, roads, airports, canal works, etc.

It is also be used to build harbors, bridges, airports, buildings, roads, rails, infrastructure, solar power, wind turbines, walls, and many other foundation types.

Hydraulic vibrating pile drivers take the advantage of high-frequency vibration generated by the motor and transmit the vibration force to the hydraulic vibrating pile driver. Lead to changes in soil around pile structure for vibration and strength decrease.

Liquefaction of soil around the pile body, reducing pile side friction and soil resistance, and under excavator pressure, vibration pile hammer and pile weight sank to the soil.

We recommend suitable pile driver attachments according to different piles.

Why did you choose Ray Attachments, the vibration pile driver?

We are professionals in excavator attachments and we have much experience in the construction industry.

Our machine: Machining center, CNC boring machine, CNC milling machine, digital boring and milling machine, CNC gantry machining center.

Especially, the CNC gantry machining center, ensures precision and concentricity and pile drive with longer service life.

| Model | Unit | RV-100 | RV-150 | RV-250 | RV-280 | RV-300 | RV-330 | RV-350 | RV-400 |

| Vibration Frequency | rpm | 2500 | 2500 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure | Mpa | 30 | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force | kn | 117 | 172 | 265 | 335 | 350 | 372 | 455 | 485 |

| Max. Pile Length | Standard(m) | 4 | 5 | 7 | 7 | 7 | 8 | 8 | 8 |

| Cylinder down(m) | 6 | 8 | 9 | 9 | 9 | 10 | 10 | 10 | |

| Extension arm(m) | / | / | 12 | 12 | 13 | 15 | 18 | 18 | |

| Arm Weight | kg | 160 | 260 | 500 | 500 | 670 | 670 | 750 | 750 |

| Arm Size | mm | 1242*300*710 | 1800*300*750 | 2600*500*900 | 2600*500*900 | 2650*600*900 | 2650*600*900 | 2700*500*940 | 2700*500*940 |

| Hammer Size | mm | 1160*960*1003 | 1210*1050*1120 | 1500*1110*1400 | 1500*1300*1500 | 1750*1450*1350 | 1750*1450*1350 | 1850*1600*1550 | 1850*1600*1550 |

| Hammer Weight | kg | 850 | 1100 | 1700 | 1900 | 2100 | 2300 | 2600 | 2700 |

| Excavator | T | 7-12 | 12-17 | 20-25 | 25-30 | 30-33 | 33-38 | 38-45 | 45-52 |

1. High efficiency: the speed of vibration pile sinking and pulling is 4-7m/min, and the fastest is 12m/min( in non-silty soil).

2. Multiple functions: Except for various piles, it can also build thin-wall anti-seepage walls, deep compaction treatment, ground compaction treatment, and other special constructions.

3. Environmental protection: lower noise, no pollution, high-frequency hydraulic pile drivers can fully meet the environmental protection requirements.

4. Wide range of functions: Suitable for any shape and material: steel pipe piles and concrete pipe piles, wood piles, etc.

RAY Vibro hammer is a machine used to drive piles in/out of the ground for constructing structures like bridges, harbors, roads, airports, canal works, etc.

It is also be used to build harbors, bridges, airports, buildings, roads, rails, infrastructure, solar power, wind turbines, walls, and many other foundation types.

Hydraulic vibrating pile drivers take the advantage of high-frequency vibration generated by the motor and transmit the vibration force to the hydraulic vibrating pile driver. Lead to changes in soil around pile structure for vibration and strength decrease.

Liquefaction of soil around the pile body, reducing pile side friction and soil resistance, and under excavator pressure, vibration pile hammer and pile weight sank to the soil.

We recommend suitable pile driver attachments according to different piles.

Why did you choose Ray Attachments, the vibration pile driver?

We are professionals in excavator attachments and we have much experience in the construction industry.

Our machine: Machining center, CNC boring machine, CNC milling machine, digital boring and milling machine, CNC gantry machining center.

Especially, the CNC gantry machining center, ensures precision and concentricity and pile drive with longer service life.