REA12000

RAYATTACHMENTS

| Availability: | |

|---|---|

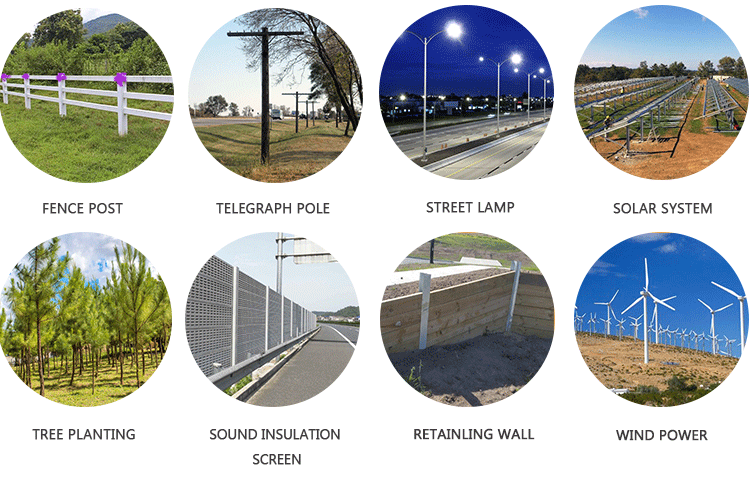

Auger Drives REA10000 up to REA25000 are the perfect choice for excavators between 10T and 23T.

Even though these model Auger Drives are the smallest in our line-up they are over engineered and built to last, giving you the same versatility, peace of mind and product quality you’d expect from all our products. Developed to work with all makes and models of parent machine, and complemented with a range of attachments, you will find an earth auger and attachment for your every need. With the versatility to easily switch between attachments depending on the job at hand, you can be sure that your RAY Earth Auger will deliver, time and again.

Auger Drives REA5000 up to REA8000 are the perfect choice for small excavators between 4.5T-12T.

Auger Drives REA10000 up to REA25000 are the perfect choice for excavators between 10T and 23T.

Auger Drives REA50000 up to REA65000 are the perfect choice for excavators between 20T and 50T.

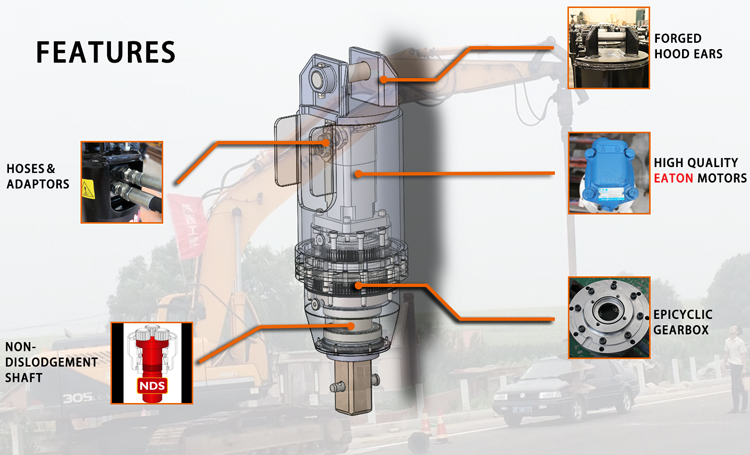

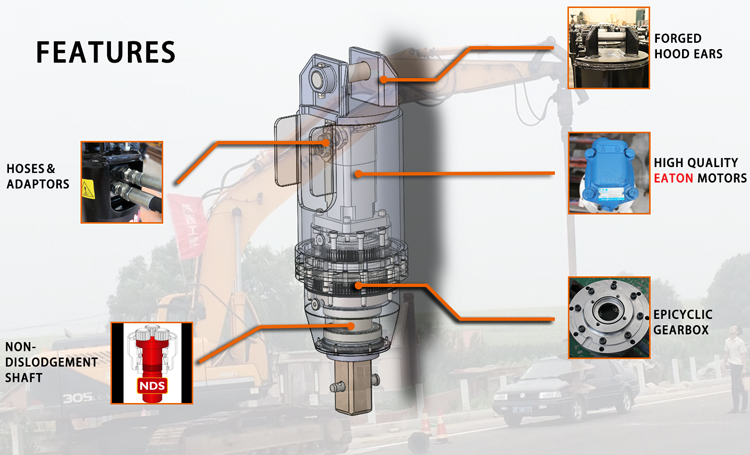

Standard with all Auger Drives in areas that we know will take a lot of strain. All hood pins are locked for extra safety making it impossible for the hood to detach from your hitch

EATON Motor provide stable and high torque power output. The failure rate is only 0.2%

Torque is amplified by using the unique planetary gearbox. This system allows the motors output torque to be multiplied with extreme efficiency as well as ensuring the durability and reliability you need.

The Non-Dislodgement Shaft is a single piece drive shaft assembled top down and locked into the Earth Drill housing. This design guarantees that the shaft will never fall out, making for a safer work environment, not only for the operator but also any surrounding workers, a MUST-HAVE FEATURE for any safety conscious company.

All Auger drives come standard with high quality hoses and adaptors (excludes larger units. QRC’s not included).

The efficiency mainly refers to the rotating speed whicj according to the oil flow of the excavator. Different working conditions and the proficiency of operators also affect it.

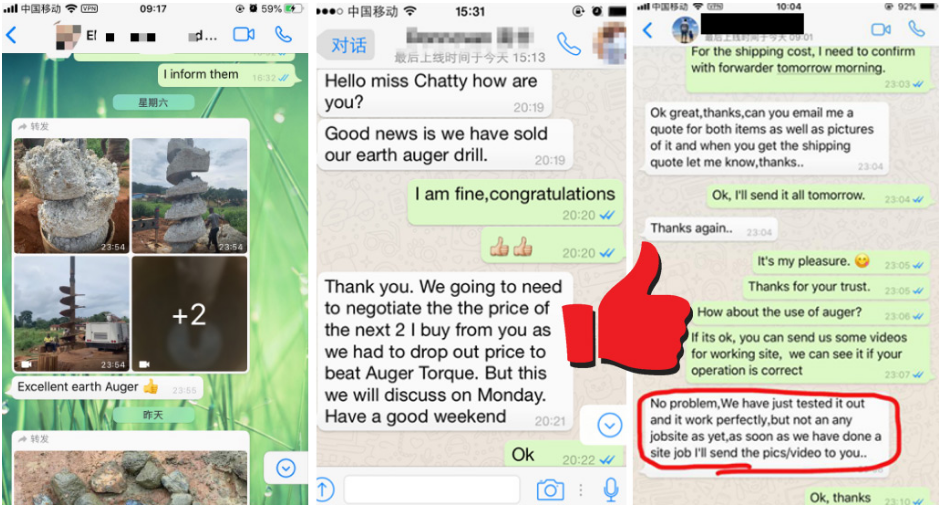

We have a client who can dig 1,500 holes in a day. His excavator is 6 tons with 350mm diameter and 500mm depth. And There is also a customers use 7 ton excavator with diameter 700mm & depth 1.8m, just 100 holes within 8 hours.

| REA Auger Drive Specification | |||||||||||||||||

| Model | Unit | REA2000 | REA2500 | REA3000 | REA3500 | REA4500 | REA5000 | REA5500 | REA6000 | REA7000 | REA8000 | REA10000 | REA12000 | REA15000 | REA20000 | REA25000 | REA50000 |

| Carrier | T | 1~2.5 | 1.5~3 | 2~3.5 | 2.5~4.5 | 3~5 | 4.5~7 | 5~7 | 6~8 | 7~10 | 8~12 | 10~13 | 13~17 | 13~17 | 13~20 | 15~23 | 21~50 |

| Torque | N.m | ≤1871 | ≤2432 | ≤2877 | ≤3614 | ≤4218 | ≤5056 | ≤5910 | ≤6150 | ≤6931 | ≤8048 | ≤10778 | ≤11976 | ≤15046 | ≤19039 | ≤24949 | ≤50195 |

| Pressure | Bar | 205 | 205 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 250 | 280 |

| Oil Flow Range | l/min | 23~53 | 30~61 | 30~61 | 30~68 | 38~76 | 38~76 | 45~83 | 45~106 | 61~121 | 61~136 | 70~136 | 80~140 | 80~151 | 80~170 | 90~180 | 100-280 |

| Rotary Speed | rpm | 40~92 | 40~82 | 40~81 | 32~72 | 32~64 | 29~58 | 28~50 | 34~80 | 37~72 | 29~64 | 26~45 | 22~43 | 20~39 | 17~34 | 16~30 | 11~30 |

| Hydraulic Hose | Inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 1 1/2 |

| Output Shaft | mm | Ф65 | Ф65 | Ф65 | Ф65 | Ф65 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □110 |

| Unit Weight | Kg | 54 | 54 | 71 | 71 | 71 | 108 | 108 | 110 | 112 | 115 | 167 | 167 | 167 | 185 | 185 | 480 |

| Unit Height | mm | 595 | 595 | 700 | 700 | 700 | 780 | 780 | 850 | 850 | 850 | 930 | 930 | 930 | 930 | 930 | 14320 |

| Unit Max.Dia. | mm | 200 | 200 | 244 | 244 | 244 | 269 | 269 | 269 | 269 | 269 | 290 | 290 | 290 | 290 | 290 | 450 |

| Auger Series | mm | S4 | S4 | S4 | S4 | S4 | S5 | S5 | S5 | S5 | S5 | S6 | S6 | S6 | S6 | S6 | PA |

| Auger Length | mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1500 | 1500 | 1500 | 1500 | 1500 | 1750 | 1750 | 1750 | 1750 | 1750 | 2300 |

| Auger dia. Range | mm | 100~400 | 100~500 | 100~600 | 100~750 | 100~900 | 150~600 | 150~750 | 150~900 | 150~900 | 150~900 | 150~900 | 150~900 | 150~1200 | 150~1200 | 150~1200 | 300-2400 |

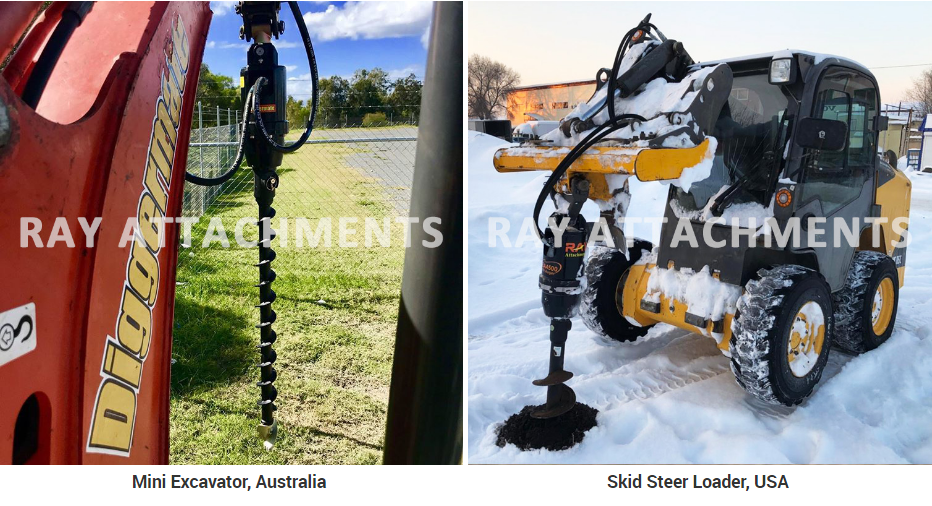

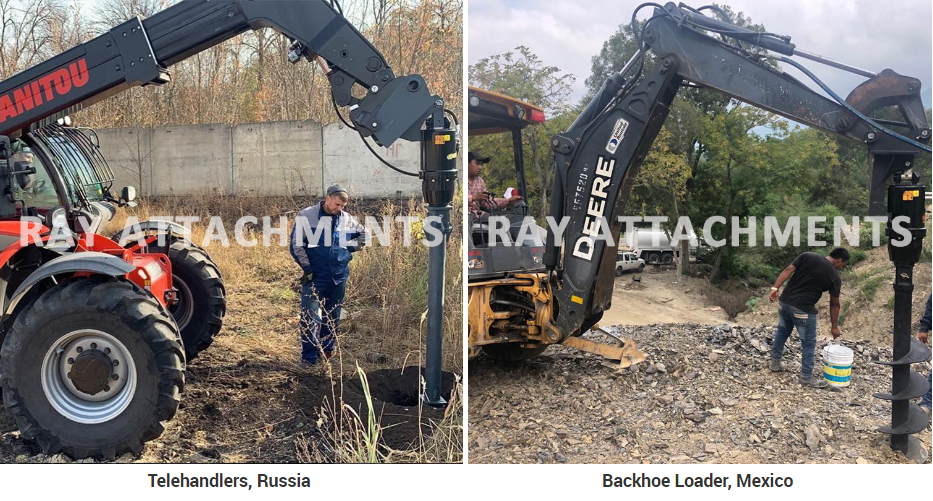

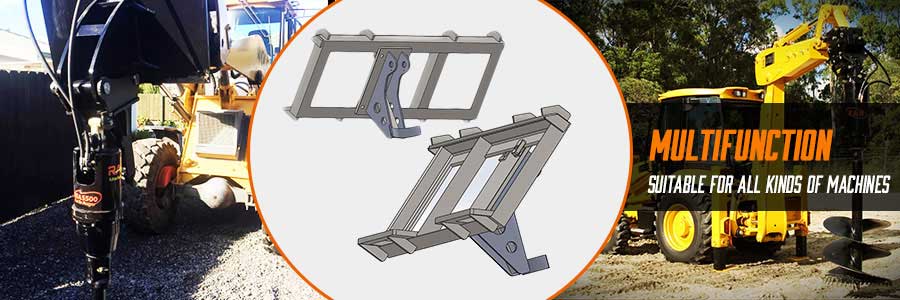

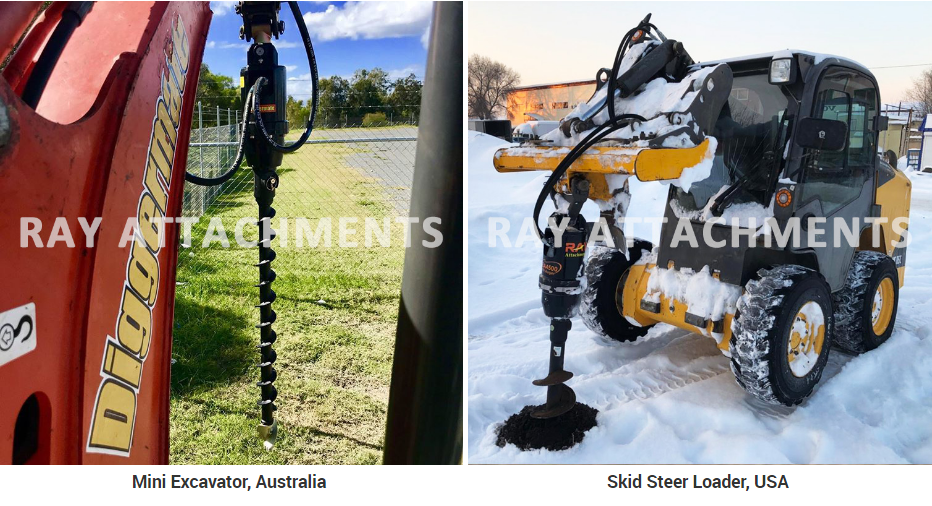

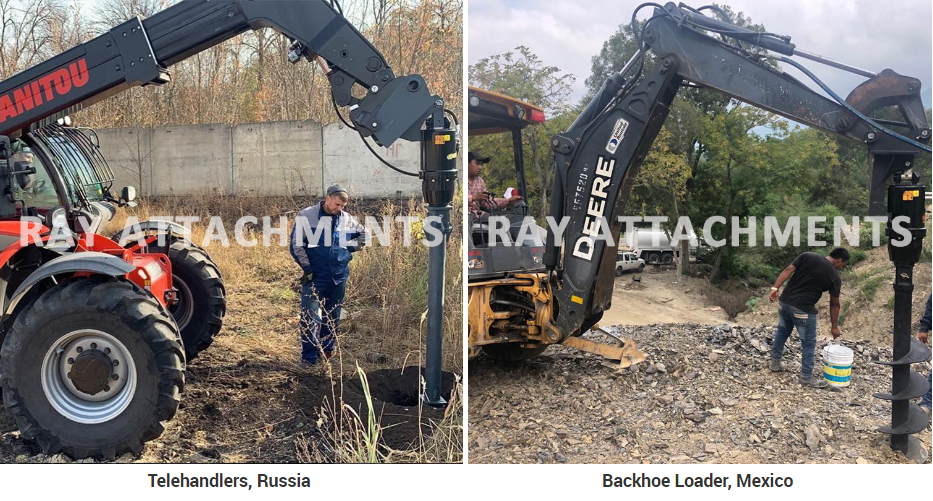

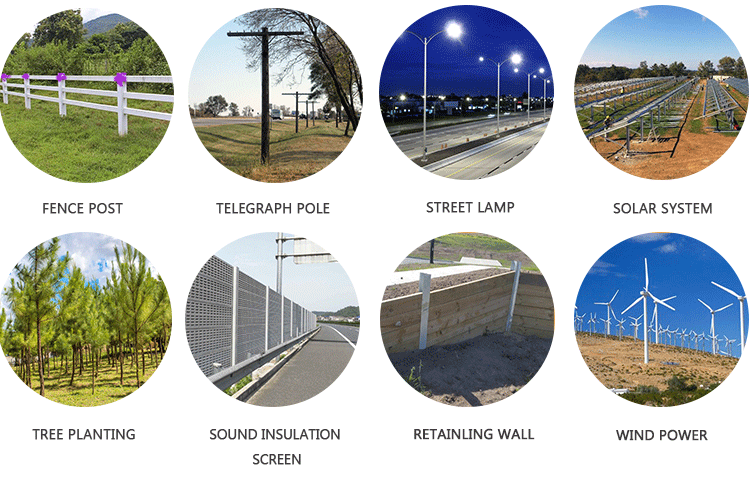

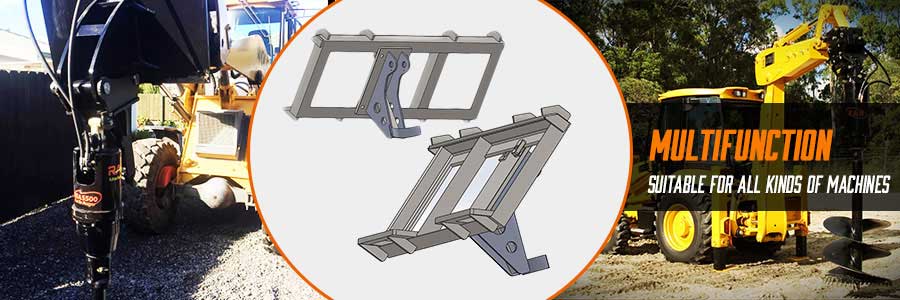

RAY Earth Auger can be mounted on Excavator, Skid steer loader, Crane, Backhoe loader, Tractor, Telehandlers...

18 years OEM & ODM experience.

We can provide professional OEM and ODM service, such as customize your own colour, brand, package and so on.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

1.Q:In which condition, auger will craze?

A:Wrong operation will lead auger crazing. Auger should be vertical to the earth when operation. Big type auger drive has reinforcement measure to protect auger.

2.Q:Will the screw blade drop out?

A:No, we haven’t met this condition so far.

3.Q:What’s the gear box used for in the auger drive?

A:The planetary gear is used for transmission. Gear box is used for slowing down the speed of motor.

4.Q:In which condition, earth auger can work most efficient?

A:Efficiency depends on rotate speed. Rotate speed depends on oil flow. Oil flow depends on the excavator pump.

5.Q:In common earth condition, how many holes can be dig in 1 min?

A:Different earth condition has different answer. It depends on the oil flow and pressure, whether the earth loose. For example, it takes 30s to dig a dia 300, depth 1.5m hole in loose earth.

6.Q:How long should change the auger teeth?

A:It depends on the earth condition and working time. According to customers’ feedback, it would be 6 months in loose earth and 1-3 moths in soil with small stones.

7.Q:What’s the space between two screw blade?

A:It depends on the auger type and the outer diameter.

8.Q:What’s the material of screw blade?

A:Q345 alloy steel.

9.Q:Why the output shaft of REA2000-4500 is round, and REA5000-25000 is square?

A:Large type of auger drive has bigger torque. Square output shaft can increase the friction and hard to slide.

10.Q:In which condition, the auger drive won’s work.

A:The hose was not connected correctly. The excavator problem. The motor problem.

11.Q:How about the warranty?

A:We provide 18 month warranty for our auger drive.(Under the correct operation)

12.Q:How many teeth does S4,S5,S6 auger have? According to diameter of the auger?

A:Yes, according to the auger’s diameter.

13.Q:Why don’t fully weld between screw blade and auger?

A:Because fully weld will make the auger deformation.

14.Q:Will the teeth holder be deformed.

A:It will be worn but won’t be deformed.

15.Q:What’s the material of the teeth and what’s the technology?

A:The material is tungsten and the technology is forged.

16.Q:How many oil seal does a auger drive have. How long should change the oil seal?

A:4 oil seal. It don’t need to change in general.

17.Q:Oil seal must be changed by manufacture? Or customers can change it by themselves?

A:All the oil seal are normal. You can change it by yourself.

18.Q:Why do the auger drive leak oil?

A:There may be some problems of oil seal.

19.Q:What kind of machine can auger drive be installed?

A:Excavator, crane and skip steer loader.

20.Q:What’s the material of the pin hitch?

A:Q345.

21.Q:Why the thickness of screw blade is different? What’s the thickness of central pole? Why the thickness of central pole is different?

A:Because of different type, big torque will make the auger broker.

The thickness of central pole: S4 6mm, S5 8mm, S6 12mm.

22.Q:Why don’t make auger longer, a 2-3m long?

A:We can do this, but it may not be lift up.

Auger Drives REA10000 up to REA25000 are the perfect choice for excavators between 10T and 23T.

Even though these model Auger Drives are the smallest in our line-up they are over engineered and built to last, giving you the same versatility, peace of mind and product quality you’d expect from all our products. Developed to work with all makes and models of parent machine, and complemented with a range of attachments, you will find an earth auger and attachment for your every need. With the versatility to easily switch between attachments depending on the job at hand, you can be sure that your RAY Earth Auger will deliver, time and again.

Auger Drives REA5000 up to REA8000 are the perfect choice for small excavators between 4.5T-12T.

Auger Drives REA10000 up to REA25000 are the perfect choice for excavators between 10T and 23T.

Auger Drives REA50000 up to REA65000 are the perfect choice for excavators between 20T and 50T.

Standard with all Auger Drives in areas that we know will take a lot of strain. All hood pins are locked for extra safety making it impossible for the hood to detach from your hitch

EATON Motor provide stable and high torque power output. The failure rate is only 0.2%

Torque is amplified by using the unique planetary gearbox. This system allows the motors output torque to be multiplied with extreme efficiency as well as ensuring the durability and reliability you need.

The Non-Dislodgement Shaft is a single piece drive shaft assembled top down and locked into the Earth Drill housing. This design guarantees that the shaft will never fall out, making for a safer work environment, not only for the operator but also any surrounding workers, a MUST-HAVE FEATURE for any safety conscious company.

All Auger drives come standard with high quality hoses and adaptors (excludes larger units. QRC’s not included).

The efficiency mainly refers to the rotating speed whicj according to the oil flow of the excavator. Different working conditions and the proficiency of operators also affect it.

We have a client who can dig 1,500 holes in a day. His excavator is 6 tons with 350mm diameter and 500mm depth. And There is also a customers use 7 ton excavator with diameter 700mm & depth 1.8m, just 100 holes within 8 hours.

| REA Auger Drive Specification | |||||||||||||||||

| Model | Unit | REA2000 | REA2500 | REA3000 | REA3500 | REA4500 | REA5000 | REA5500 | REA6000 | REA7000 | REA8000 | REA10000 | REA12000 | REA15000 | REA20000 | REA25000 | REA50000 |

| Carrier | T | 1~2.5 | 1.5~3 | 2~3.5 | 2.5~4.5 | 3~5 | 4.5~7 | 5~7 | 6~8 | 7~10 | 8~12 | 10~13 | 13~17 | 13~17 | 13~20 | 15~23 | 21~50 |

| Torque | N.m | ≤1871 | ≤2432 | ≤2877 | ≤3614 | ≤4218 | ≤5056 | ≤5910 | ≤6150 | ≤6931 | ≤8048 | ≤10778 | ≤11976 | ≤15046 | ≤19039 | ≤24949 | ≤50195 |

| Pressure | Bar | 205 | 205 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 250 | 280 |

| Oil Flow Range | l/min | 23~53 | 30~61 | 30~61 | 30~68 | 38~76 | 38~76 | 45~83 | 45~106 | 61~121 | 61~136 | 70~136 | 80~140 | 80~151 | 80~170 | 90~180 | 100-280 |

| Rotary Speed | rpm | 40~92 | 40~82 | 40~81 | 32~72 | 32~64 | 29~58 | 28~50 | 34~80 | 37~72 | 29~64 | 26~45 | 22~43 | 20~39 | 17~34 | 16~30 | 11~30 |

| Hydraulic Hose | Inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 1 1/2 |

| Output Shaft | mm | Ф65 | Ф65 | Ф65 | Ф65 | Ф65 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □75 | □110 |

| Unit Weight | Kg | 54 | 54 | 71 | 71 | 71 | 108 | 108 | 110 | 112 | 115 | 167 | 167 | 167 | 185 | 185 | 480 |

| Unit Height | mm | 595 | 595 | 700 | 700 | 700 | 780 | 780 | 850 | 850 | 850 | 930 | 930 | 930 | 930 | 930 | 14320 |

| Unit Max.Dia. | mm | 200 | 200 | 244 | 244 | 244 | 269 | 269 | 269 | 269 | 269 | 290 | 290 | 290 | 290 | 290 | 450 |

| Auger Series | mm | S4 | S4 | S4 | S4 | S4 | S5 | S5 | S5 | S5 | S5 | S6 | S6 | S6 | S6 | S6 | PA |

| Auger Length | mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1500 | 1500 | 1500 | 1500 | 1500 | 1750 | 1750 | 1750 | 1750 | 1750 | 2300 |

| Auger dia. Range | mm | 100~400 | 100~500 | 100~600 | 100~750 | 100~900 | 150~600 | 150~750 | 150~900 | 150~900 | 150~900 | 150~900 | 150~900 | 150~1200 | 150~1200 | 150~1200 | 300-2400 |

RAY Earth Auger can be mounted on Excavator, Skid steer loader, Crane, Backhoe loader, Tractor, Telehandlers...

18 years OEM & ODM experience.

We can provide professional OEM and ODM service, such as customize your own colour, brand, package and so on.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

1.Q:In which condition, auger will craze?

A:Wrong operation will lead auger crazing. Auger should be vertical to the earth when operation. Big type auger drive has reinforcement measure to protect auger.

2.Q:Will the screw blade drop out?

A:No, we haven’t met this condition so far.

3.Q:What’s the gear box used for in the auger drive?

A:The planetary gear is used for transmission. Gear box is used for slowing down the speed of motor.

4.Q:In which condition, earth auger can work most efficient?

A:Efficiency depends on rotate speed. Rotate speed depends on oil flow. Oil flow depends on the excavator pump.

5.Q:In common earth condition, how many holes can be dig in 1 min?

A:Different earth condition has different answer. It depends on the oil flow and pressure, whether the earth loose. For example, it takes 30s to dig a dia 300, depth 1.5m hole in loose earth.

6.Q:How long should change the auger teeth?

A:It depends on the earth condition and working time. According to customers’ feedback, it would be 6 months in loose earth and 1-3 moths in soil with small stones.

7.Q:What’s the space between two screw blade?

A:It depends on the auger type and the outer diameter.

8.Q:What’s the material of screw blade?

A:Q345 alloy steel.

9.Q:Why the output shaft of REA2000-4500 is round, and REA5000-25000 is square?

A:Large type of auger drive has bigger torque. Square output shaft can increase the friction and hard to slide.

10.Q:In which condition, the auger drive won’s work.

A:The hose was not connected correctly. The excavator problem. The motor problem.

11.Q:How about the warranty?

A:We provide 18 month warranty for our auger drive.(Under the correct operation)

12.Q:How many teeth does S4,S5,S6 auger have? According to diameter of the auger?

A:Yes, according to the auger’s diameter.

13.Q:Why don’t fully weld between screw blade and auger?

A:Because fully weld will make the auger deformation.

14.Q:Will the teeth holder be deformed.

A:It will be worn but won’t be deformed.

15.Q:What’s the material of the teeth and what’s the technology?

A:The material is tungsten and the technology is forged.

16.Q:How many oil seal does a auger drive have. How long should change the oil seal?

A:4 oil seal. It don’t need to change in general.

17.Q:Oil seal must be changed by manufacture? Or customers can change it by themselves?

A:All the oil seal are normal. You can change it by yourself.

18.Q:Why do the auger drive leak oil?

A:There may be some problems of oil seal.

19.Q:What kind of machine can auger drive be installed?

A:Excavator, crane and skip steer loader.

20.Q:What’s the material of the pin hitch?

A:Q345.

21.Q:Why the thickness of screw blade is different? What’s the thickness of central pole? Why the thickness of central pole is different?

A:Because of different type, big torque will make the auger broker.

The thickness of central pole: S4 6mm, S5 8mm, S6 12mm.

22.Q:Why don’t make auger longer, a 2-3m long?

A:We can do this, but it may not be lift up.

1.Q:In which condition, auger will craze?

A:Wrong operation will lead auger crazing. Auger should be vertical to the earth when operation. Big type auger drive has reinforcement measure to protect auger.

2.Q:Will the screw blade drop out?

A:No, we haven’t met this condition so far.

3.Q:What’s the gear box used for in the auger drive?

A:The planetary gear is used for transmission. Gear box is used for slowing down the speed of motor.

4.Q:In which condition, earth auger can work most efficient?

A:Efficiency depends on rotate speed. Rotate speed depends on oil flow. Oil flow depends on the excavator pump.

5.Q:In common earth condition, how many holes can be dig in 1 min?

A:Different earth condition has different answer. It depends on the oil flow and pressure, whether the earth loose. For example, it takes 30s to dig a dia 300, depth 1.5m hole in loose earth.

6.Q:How long should change the auger teeth?

A:It depends on the earth condition and working time. According to customers’ feedback, it would be 6 months in loose earth and 1-3 moths in soil with small stones.

7.Q:What’s the space between two screw blade?

A:It depends on the auger type and the outer diameter.

8.Q:What’s the material of screw blade?

A:Q345 alloy steel.

9.Q:Why the output shaft of REA2000-4500 is round, and REA5000-25000 is square?

A:Large type of auger drive has bigger torque. Square output shaft can increase the friction and hard to slide.

10.Q:In which condition, the auger drive won’s work.

A:The hose was not connected correctly. The excavator problem. The motor problem.

11.Q:How about the warranty?

A:We provide 18 month warranty for our auger drive.(Under the correct operation)

12.Q:How many teeth does S4,S5,S6 auger have? According to diameter of the auger?

A:Yes, according to the auger’s diameter.

13.Q:Why don’t fully weld between screw blade and auger?

A:Because fully weld will make the auger deformation.

14.Q:Will the teeth holder be deformed.

A:It will be worn but won’t be deformed.

15.Q:What’s the material of the teeth and what’s the technology?

A:The material is tungsten and the technology is forged.

16.Q:How many oil seal does a auger drive have. How long should change the oil seal?

A:4 oil seal. It don’t need to change in general.

17.Q:Oil seal must be changed by manufacture? Or customers can change it by themselves?

A:All the oil seal are normal. You can change it by yourself.

18.Q:Why do the auger drive leak oil?

A:There may be some problems of oil seal.

19.Q:What kind of machine can auger drive be installed?

A:Excavator, crane and skip steer loader.

20.Q:What’s the material of the pin hitch?

A:Q345.

21.Q:Why the thickness of screw blade is different? What’s the thickness of central pole? Why the thickness of central pole is different?

A:Because of different type, big torque will make the auger broker.

The thickness of central pole: S4 6mm, S5 8mm, S6 12mm.

22.Q:Why don’t make auger longer, a 2-3m long?

A:We can do this, but it may not be lift up.

1.Q:In which condition, auger will craze?

A:Wrong operation will lead auger crazing. Auger should be vertical to the earth when operation. Big type auger drive has reinforcement measure to protect auger.

2.Q:Will the screw blade drop out?

A:No, we haven’t met this condition so far.

3.Q:What’s the gear box used for in the auger drive?

A:The planetary gear is used for transmission. Gear box is used for slowing down the speed of motor.

4.Q:In which condition, earth auger can work most efficient?

A:Efficiency depends on rotate speed. Rotate speed depends on oil flow. Oil flow depends on the excavator pump.

5.Q:In common earth condition, how many holes can be dig in 1 min?

A:Different earth condition has different answer. It depends on the oil flow and pressure, whether the earth loose. For example, it takes 30s to dig a dia 300, depth 1.5m hole in loose earth.

6.Q:How long should change the auger teeth?

A:It depends on the earth condition and working time. According to customers’ feedback, it would be 6 months in loose earth and 1-3 moths in soil with small stones.

7.Q:What’s the space between two screw blade?

A:It depends on the auger type and the outer diameter.

8.Q:What’s the material of screw blade?

A:Q345 alloy steel.

9.Q:Why the output shaft of REA2000-4500 is round, and REA5000-25000 is square?

A:Large type of auger drive has bigger torque. Square output shaft can increase the friction and hard to slide.

10.Q:In which condition, the auger drive won’s work.

A:The hose was not connected correctly. The excavator problem. The motor problem.

11.Q:How about the warranty?

A:We provide 18 month warranty for our auger drive.(Under the correct operation)

12.Q:How many teeth does S4,S5,S6 auger have? According to diameter of the auger?

A:Yes, according to the auger’s diameter.

13.Q:Why don’t fully weld between screw blade and auger?

A:Because fully weld will make the auger deformation.

14.Q:Will the teeth holder be deformed.

A:It will be worn but won’t be deformed.

15.Q:What’s the material of the teeth and what’s the technology?

A:The material is tungsten and the technology is forged.

16.Q:How many oil seal does a auger drive have. How long should change the oil seal?

A:4 oil seal. It don’t need to change in general.

17.Q:Oil seal must be changed by manufacture? Or customers can change it by themselves?

A:All the oil seal are normal. You can change it by yourself.

18.Q:Why do the auger drive leak oil?

A:There may be some problems of oil seal.

19.Q:What kind of machine can auger drive be installed?

A:Excavator, crane and skip steer loader.

20.Q:What’s the material of the pin hitch?

A:Q345.

21.Q:Why the thickness of screw blade is different? What’s the thickness of central pole? Why the thickness of central pole is different?

A:Because of different type, big torque will make the auger broker.

The thickness of central pole: S4 6mm, S5 8mm, S6 12mm.

22.Q:Why don’t make auger longer, a 2-3m long?

A:We can do this, but it may not be lift up.