RVR-20

RAY ATTACHMENTS

| Availability: | |

|---|---|

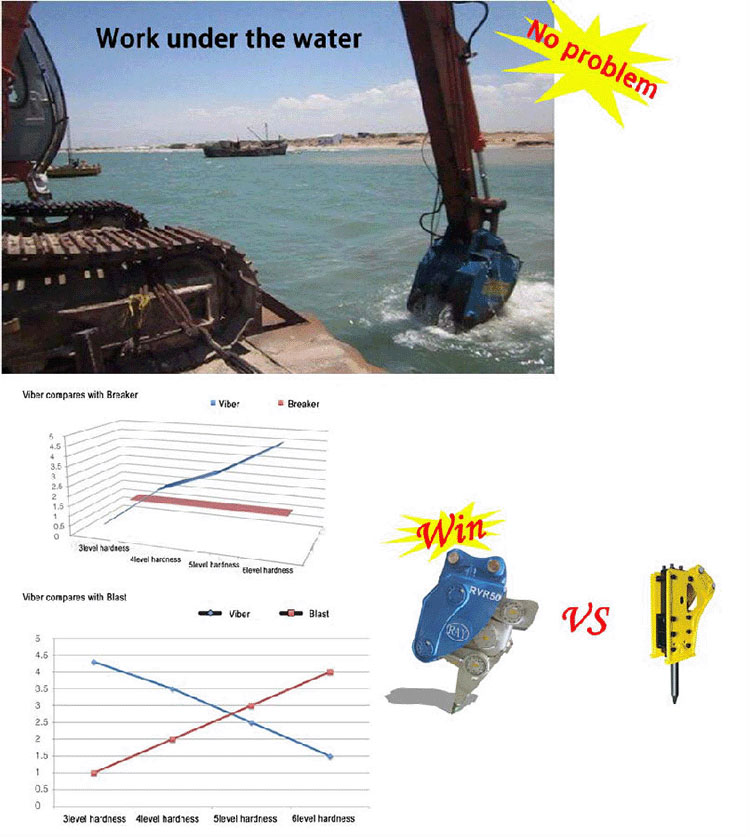

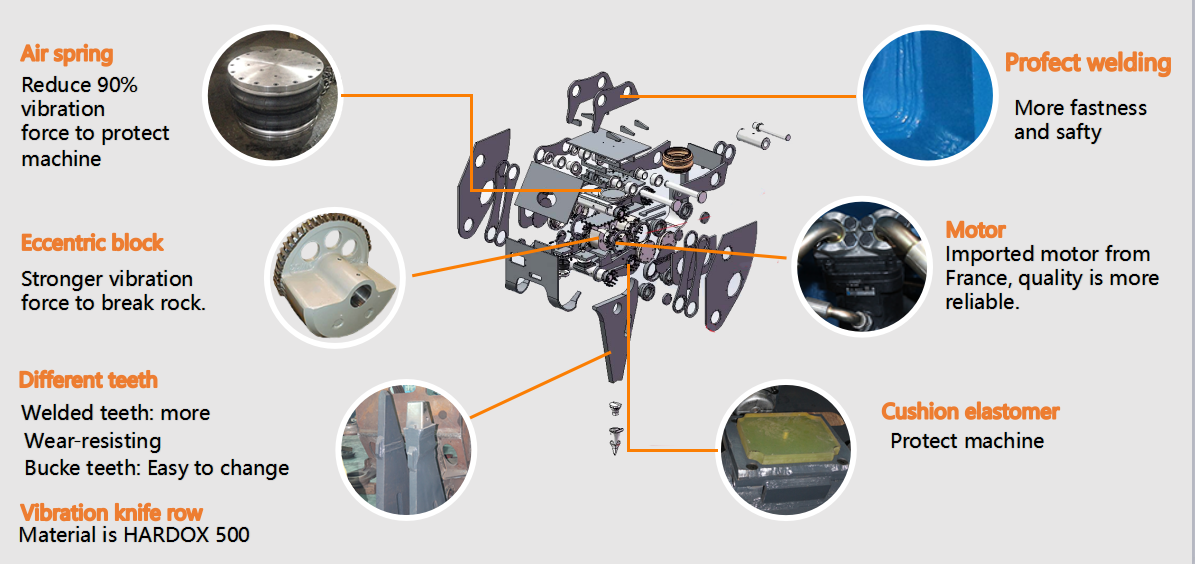

It’s a new generation attachment recently developed and manufactured to effectively excavator, crush and destroy the soft rock mass such as rocks weathered by wind and water, hard soil, slate, quartz, concrete and Asphalt.

Vibro ripper makes light work of ripping the soil to make excavation productive and easier. Practically no modification is required to switch from working on land to water. Also, inexpensive easily replaceable wear tool is provided for economical operation, this can be changed according to the strata to be ripped.

An excavator ripper is an attachment that is used to break up hard and compacted soil, rocks, and other materials. It is a highly effective tool that can be attached to an excavator to quickly and efficiently loosen soil and rocks.

Rippers for excavators come in different types and sizes depending on the job at hand. They can be used for a variety of applications such as excavation, demolition, mining, and construction.

The ripper attachment for excavators is designed to be strong and durable, able to withstand the high forces involved in ripping through tough materials. It is made of high-quality materials such as steel, and can be customized to fit any excavator.

When shopping for a ripper attachment, it is important to look for a reputable seller that offers quality products at a fair price. There are many ripper deals available in Australia, but it is important to do your research and choose a reliable supplier.

The ripper bucket is another type of attachment that can be used on an excavator. It is designed to scoop up and remove loose material after it has been ripped apart by the ripper.

Overall, an excavator ripper is an essential tool for any excavation or construction project. It can help to save time and money by quickly and efficiently breaking up tough materials, and can be customized to fit any excavator.

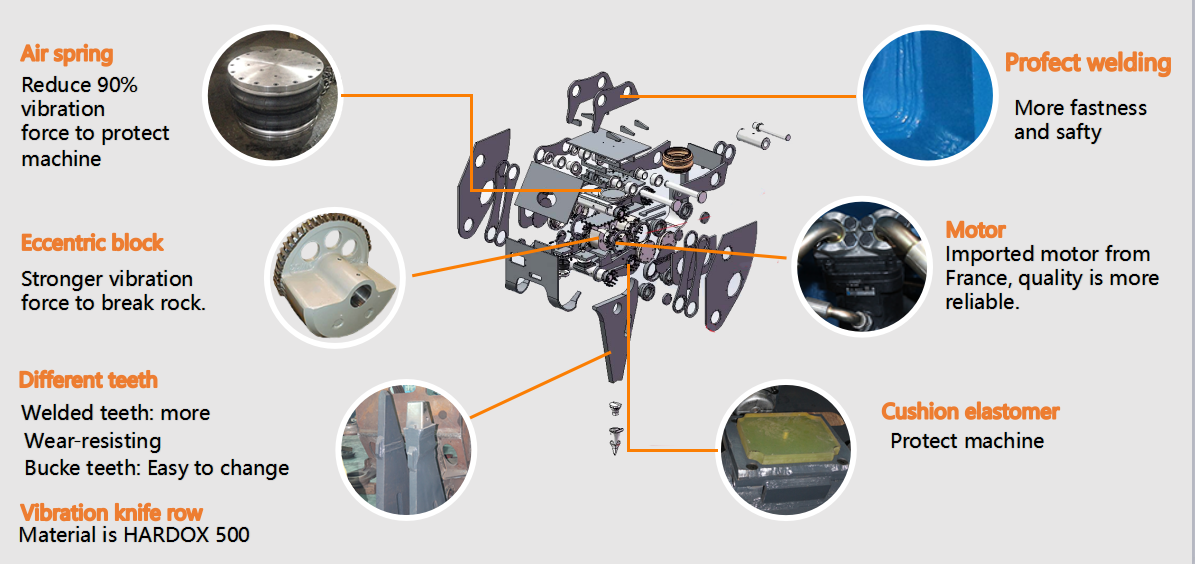

1. Enhance 3-5 times higher output (compare with regular breaker equipment)

2. Reduce synthesize fuel consumption

3. Reduce unit output emission load

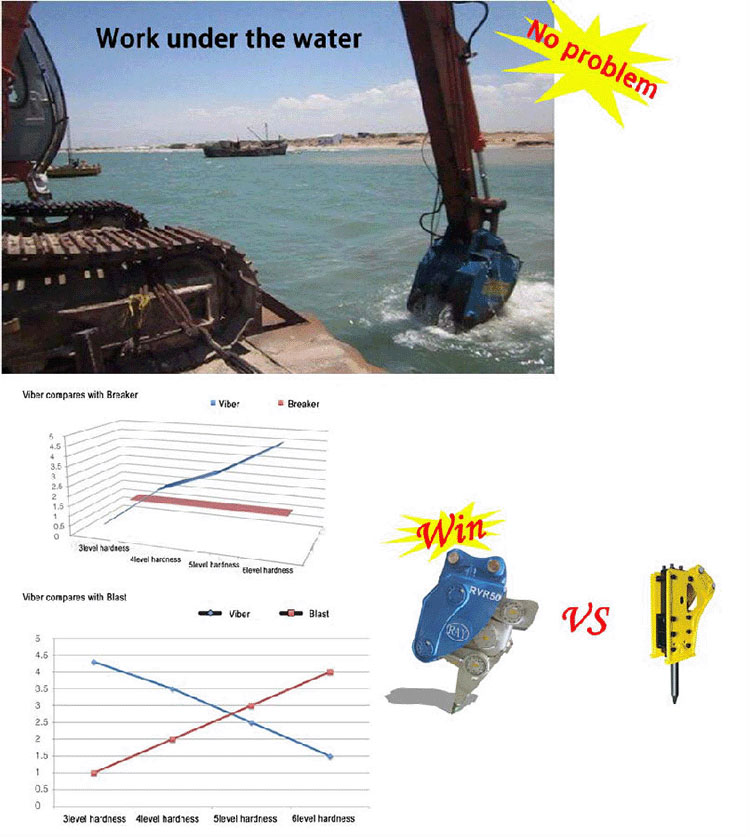

4. Work under water and subsurface without refit (10-15m)

5. Minimum damage to excavator's bumps and arms (protect excavator)

6. Enhance comfort level during operate

7. Minimum operating noise (working noise is only 50-75 db)

8. Lower maintain

9. Lower vulnerable part cost

10.Enhance parts and full equipment working life

How to choose suitable model?

1.make sure the weight of excavator:

| Model | RVR-30 | RVR-40 | RVR-50 | RVR-60 | RVR-E7 | RVR-D8 | RVR-D10 | |

| Power(KW) | 75 | 75 | 85 | 102 | 170-210 | 204-255 | 255-320 | |

| Motor (CC) | 90 | 90 | 110 | 125 | 110*2 | 125*2 | 110*3 | |

| Impact force(KN) | 295 | 315 | 385 | 450 | 550 | 750 | 860 | |

| SIZE | Length | 2780mm | 2780mm | 3235mm | 3235mm | 3765mm | 4030mm | 4340mm |

| Width | 960mm | 960mm | 1110mm | 1110mm | 1180mm | 1160mm | 1160mm | |

| Height | 1400mm | 1400mm | 1565mm | 1565mm | 1775mm | 1900mm | 2360mm | |

| Wroking flow(L/min) | 120-170 | 145-195 | 155-210 | 175-250 | 308-400 | 350-450 | 450-675 | |

| Working power(Mpa) | 26-31 | 26-31 | 26-31 | 26-31 | 31.5 | 26-31 | 26-31 | |

| Weight(Kg) | 4000 | 4300 | 5200 | 5500 | 7000 | 10000 | 14500 | |

| Excavator(T) | 20-25 | 25-29 | 30-35 | 35-45 | 46-60 | 60-90 | 80-120 | |

Make sure the hardness of Rock:

| Model | Mohs’ hardness reference table & rock type | |||

| RVR-D6,RVR-D8, RVR-D10 | 9-10 hardness level standard mineral: Marble, Adamas Weakly weathered Sandstone,conglomerate,limestone,shale,Limestone,Dolomite Moderately differentiated or Weakly weathered Sandstone,conglomerate,limesto-ne,shale,Limestone,Dolomite | |||

If you are not sure the material you can take photos and send to us. We will help you to find the most suitable model.

It’s a new generation attachment recently developed and manufactured to effectively excavator, crush and destroy the soft rock mass such as rocks weathered by wind and water, hard soil, slate, quartz, concrete and Asphalt.

Vibro ripper makes light work of ripping the soil to make excavation productive and easier. Practically no modification is required to switch from working on land to water. Also, inexpensive easily replaceable wear tool is provided for economical operation, this can be changed according to the strata to be ripped.

An excavator ripper is an attachment that is used to break up hard and compacted soil, rocks, and other materials. It is a highly effective tool that can be attached to an excavator to quickly and efficiently loosen soil and rocks.

Rippers for excavators come in different types and sizes depending on the job at hand. They can be used for a variety of applications such as excavation, demolition, mining, and construction.

The ripper attachment for excavators is designed to be strong and durable, able to withstand the high forces involved in ripping through tough materials. It is made of high-quality materials such as steel, and can be customized to fit any excavator.

When shopping for a ripper attachment, it is important to look for a reputable seller that offers quality products at a fair price. There are many ripper deals available in Australia, but it is important to do your research and choose a reliable supplier.

The ripper bucket is another type of attachment that can be used on an excavator. It is designed to scoop up and remove loose material after it has been ripped apart by the ripper.

Overall, an excavator ripper is an essential tool for any excavation or construction project. It can help to save time and money by quickly and efficiently breaking up tough materials, and can be customized to fit any excavator.

1. Enhance 3-5 times higher output (compare with regular breaker equipment)

2. Reduce synthesize fuel consumption

3. Reduce unit output emission load

4. Work under water and subsurface without refit (10-15m)

5. Minimum damage to excavator's bumps and arms (protect excavator)

6. Enhance comfort level during operate

7. Minimum operating noise (working noise is only 50-75 db)

8. Lower maintain

9. Lower vulnerable part cost

10.Enhance parts and full equipment working life

How to choose suitable model?

1.make sure the weight of excavator:

| Model | RVR-30 | RVR-40 | RVR-50 | RVR-60 | RVR-E7 | RVR-D8 | RVR-D10 | |

| Power(KW) | 75 | 75 | 85 | 102 | 170-210 | 204-255 | 255-320 | |

| Motor (CC) | 90 | 90 | 110 | 125 | 110*2 | 125*2 | 110*3 | |

| Impact force(KN) | 295 | 315 | 385 | 450 | 550 | 750 | 860 | |

| SIZE | Length | 2780mm | 2780mm | 3235mm | 3235mm | 3765mm | 4030mm | 4340mm |

| Width | 960mm | 960mm | 1110mm | 1110mm | 1180mm | 1160mm | 1160mm | |

| Height | 1400mm | 1400mm | 1565mm | 1565mm | 1775mm | 1900mm | 2360mm | |

| Wroking flow(L/min) | 120-170 | 145-195 | 155-210 | 175-250 | 308-400 | 350-450 | 450-675 | |

| Working power(Mpa) | 26-31 | 26-31 | 26-31 | 26-31 | 31.5 | 26-31 | 26-31 | |

| Weight(Kg) | 4000 | 4300 | 5200 | 5500 | 7000 | 10000 | 14500 | |

| Excavator(T) | 20-25 | 25-29 | 30-35 | 35-45 | 46-60 | 60-90 | 80-120 | |

Make sure the hardness of Rock:

| Model | Mohs’ hardness reference table & rock type | |||

| RVR-D6,RVR-D8, RVR-D10 | 9-10 hardness level standard mineral: Marble, Adamas Weakly weathered Sandstone,conglomerate,limestone,shale,Limestone,Dolomite Moderately differentiated or Weakly weathered Sandstone,conglomerate,limesto-ne,shale,Limestone,Dolomite | |||

If you are not sure the material you can take photos and send to us. We will help you to find the most suitable model.

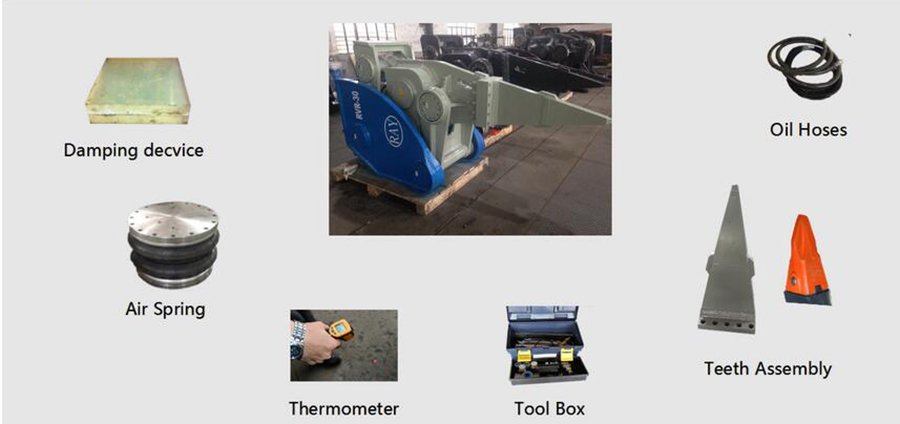

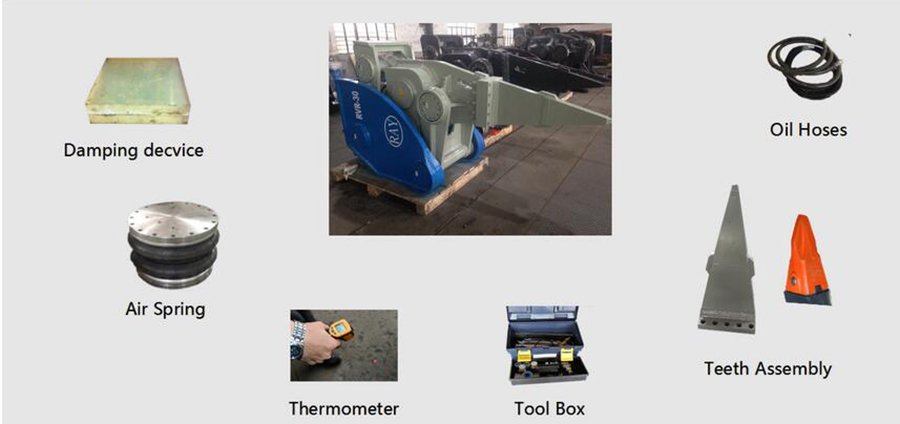

Extra spare parts for free

1. Teeth assembly: 1 piece

2. Air spring: 1 pieces

3. Damping device: 1 piece

4. Common tools: a few of pieces

5. Thermometer: 1 piece

Extra spare parts for free

1. Teeth assembly: 1 piece

2. Air spring: 1 pieces

3. Damping device: 1 piece

4. Common tools: a few of pieces

5. Thermometer: 1 piece