SH Eagle shear

RAY ATTACHMENTS

| Availability: | |

|---|---|

The scrap shear( SH EAGLE Shear)can be used in all industrial demolition sites for the cutting and recovery of ferrous materials such as iron sections, pipes, tanks, railway carriages etc. that later may be easily recycled. All Eagle Shears blades can be changed quickly and easily, minimizing machinery downtime,optimzing productivity.The Eagle Shear range are fitted with power valves to increase productivity greatly.Its range is manufactured from the highest grade steels,ensuring the maximum tool strength with the best possible wear resistance.

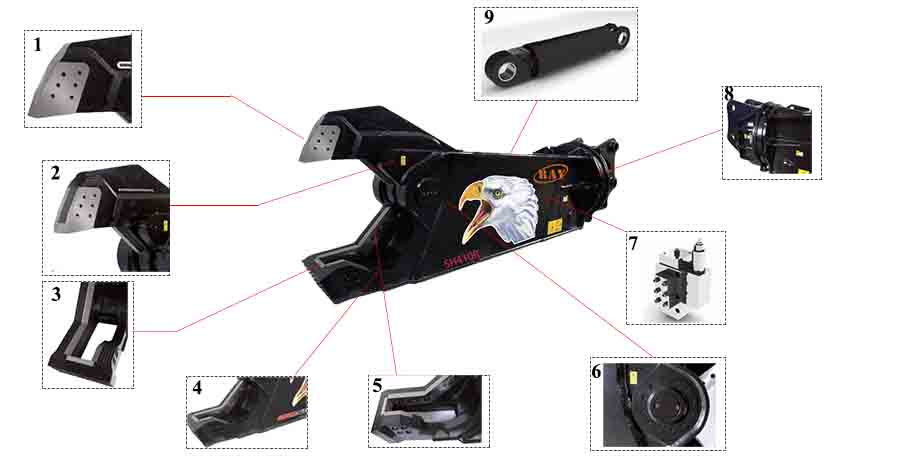

1.New Pearcing Tip:Bolted blades on piecrcing tip for fast Replacement.Eliminates time consuming rebuilding of the tip.

2.Double Guide:Twin guide for the movable jaw,ensures perfect alignment.

3.Frontal Blade:The front blade ensure accurate shearing with the tip and can be turned.

4.New Jaw design:New fixed jaw design increase cutting capacity,material is eased to fall away easily.

5.All New Blades:All the blades have been redesigned in a rhomboid shape to reduce stress on the jaw.Each blade can be turned effectively 3 times.The new blade are threaded for easier removal and installation.

6. Central Pin Adjustment Kit: Mantovanibenne have a unique central pivot pin layout. This allows for regular adjustment of the pin to ensure perfect shearing. While fully protected the pin can be removed for maintenance of all related parts.

7. Special Speed Valve: Reduced cycle times Regenerating power when required.Protection for the shear eliminating pressure peaks.

8. Rotating Group with Anticavitation Valve:360° continuous rotation. Always the best positioning of the shear.

9. All New Cylinders: Increased cylinder size for 20% more power. Forged cylinder rod for a better functionality and security . Reversed cylinder installation for full rod protection.

Tip 1: Makesure of the weight of excavator, the oil flow and the working pressure of your excavator.

| Model | SH130R | SH180R | SH310R | SH410R | |

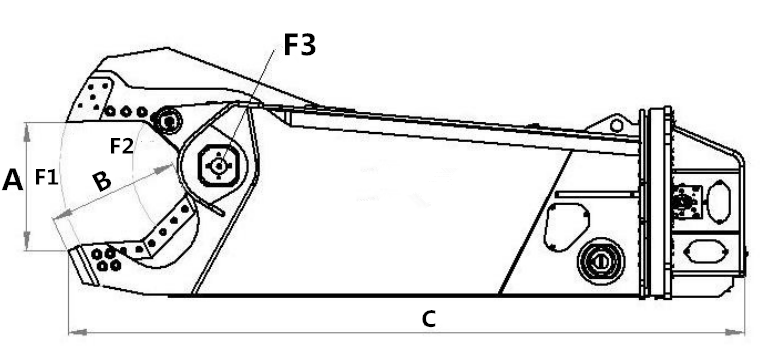

| Jaw opening (A) | mm | 375 | 445 | 565 | 670 |

| Jaw depth(B) | mm | 395 | 525 | 630 | 720 |

| Length(C) | mm | 2100 | 2700 | 3300 | 3700 |

| Excavator Weight with bucket place | t | 13-17 | 18-27 | 28-39 | 39-50 |

| Excavator Weight with stick place | t | 8-12 | 14-18 | 20-28 | 28-39 |

| Tool Weight | kg | 1220 | 2100 | 3300 | 4700 |

| Hydraulic working pressure | bar | 250-300 | 320-350 | 320-350 | 320-350 |

| Oil flow | l/min | 90-110 | 150-200 | 200-250 | 250-300 |

| Max hydraulic motor oil pressure | bar | 90-100 | 90-100 | 100-115 | 100-115 |

| max motor oil flow | l/min | 30-40 | 30-40 | 30-40 | 30-40 |

Tip 2: Make sure of the diameter and the cutting table of the object

| Model | SH130R | SH180R | SH310R | SH410R |

| mm | mm | mm | mm | |

| Jaw openning A | 375 | 445 | 565 | 670 |

| Jaw depth B | 395 | 525 | 630 | 720 |

| Length C | 2100 | 2700 | 3300 | 3700 |

| Force at upper tips F1 | 55 | 75 | 110 | 151 |

| Cutting force F2 (main blade centre) | 138 | 198 | 286 | 413 |

| Force at pin F3 | 472 | 770 | 1031 | 1372 |

![6]K}B7KM6EZ3GH43GR{`5V.png 6]K}B7KM6EZ3GH43GR{`5V.png](http://5irorwxhrkokrij.ldycdn.com/cloud/iqBqkKorRijSjikkomin/6-K-B7KM6E.png)

The scrap shear( SH EAGLE Shear)can be used in all industrial demolition sites for the cutting and recovery of ferrous materials such as iron sections, pipes, tanks, railway carriages etc. that later may be easily recycled. All Eagle Shears blades can be changed quickly and easily, minimizing machinery downtime,optimzing productivity.The Eagle Shear range are fitted with power valves to increase productivity greatly.Its range is manufactured from the highest grade steels,ensuring the maximum tool strength with the best possible wear resistance.

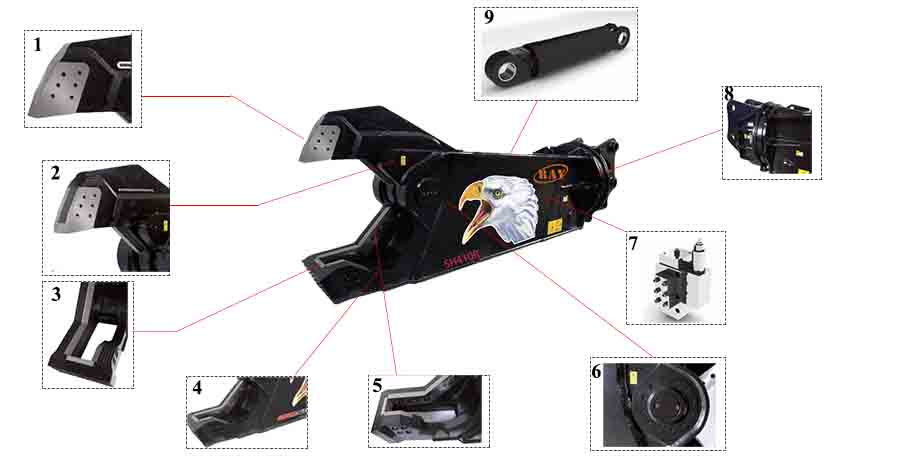

1.New Pearcing Tip:Bolted blades on piecrcing tip for fast Replacement.Eliminates time consuming rebuilding of the tip.

2.Double Guide:Twin guide for the movable jaw,ensures perfect alignment.

3.Frontal Blade:The front blade ensure accurate shearing with the tip and can be turned.

4.New Jaw design:New fixed jaw design increase cutting capacity,material is eased to fall away easily.

5.All New Blades:All the blades have been redesigned in a rhomboid shape to reduce stress on the jaw.Each blade can be turned effectively 3 times.The new blade are threaded for easier removal and installation.

6. Central Pin Adjustment Kit: Mantovanibenne have a unique central pivot pin layout. This allows for regular adjustment of the pin to ensure perfect shearing. While fully protected the pin can be removed for maintenance of all related parts.

7. Special Speed Valve: Reduced cycle times Regenerating power when required.Protection for the shear eliminating pressure peaks.

8. Rotating Group with Anticavitation Valve:360° continuous rotation. Always the best positioning of the shear.

9. All New Cylinders: Increased cylinder size for 20% more power. Forged cylinder rod for a better functionality and security . Reversed cylinder installation for full rod protection.

Tip 1: Makesure of the weight of excavator, the oil flow and the working pressure of your excavator.

| Model | SH130R | SH180R | SH310R | SH410R | |

| Jaw opening (A) | mm | 375 | 445 | 565 | 670 |

| Jaw depth(B) | mm | 395 | 525 | 630 | 720 |

| Length(C) | mm | 2100 | 2700 | 3300 | 3700 |

| Excavator Weight with bucket place | t | 13-17 | 18-27 | 28-39 | 39-50 |

| Excavator Weight with stick place | t | 8-12 | 14-18 | 20-28 | 28-39 |

| Tool Weight | kg | 1220 | 2100 | 3300 | 4700 |

| Hydraulic working pressure | bar | 250-300 | 320-350 | 320-350 | 320-350 |

| Oil flow | l/min | 90-110 | 150-200 | 200-250 | 250-300 |

| Max hydraulic motor oil pressure | bar | 90-100 | 90-100 | 100-115 | 100-115 |

| max motor oil flow | l/min | 30-40 | 30-40 | 30-40 | 30-40 |

Tip 2: Make sure of the diameter and the cutting table of the object

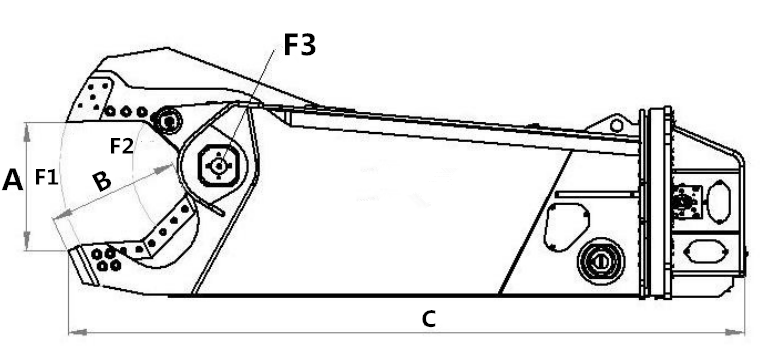

| Model | SH130R | SH180R | SH310R | SH410R |

| mm | mm | mm | mm | |

| Jaw openning A | 375 | 445 | 565 | 670 |

| Jaw depth B | 395 | 525 | 630 | 720 |

| Length C | 2100 | 2700 | 3300 | 3700 |

| Force at upper tips F1 | 55 | 75 | 110 | 151 |

| Cutting force F2 (main blade centre) | 138 | 198 | 286 | 413 |

| Force at pin F3 | 472 | 770 | 1031 | 1372 |

![6]K}B7KM6EZ3GH43GR{`5V.png 6]K}B7KM6EZ3GH43GR{`5V.png](http://5irorwxhrkokrij.ldycdn.com/cloud/iqBqkKorRijSjikkomin/6-K-B7KM6E.png)