MCP600

RAY ATTACHMENTS

| Availability: | |

|---|---|

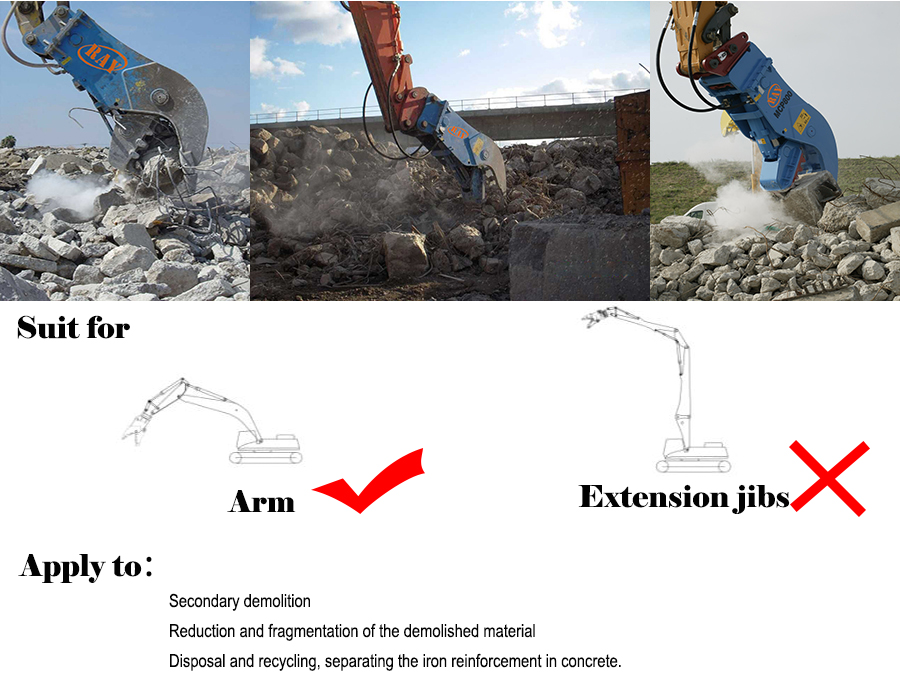

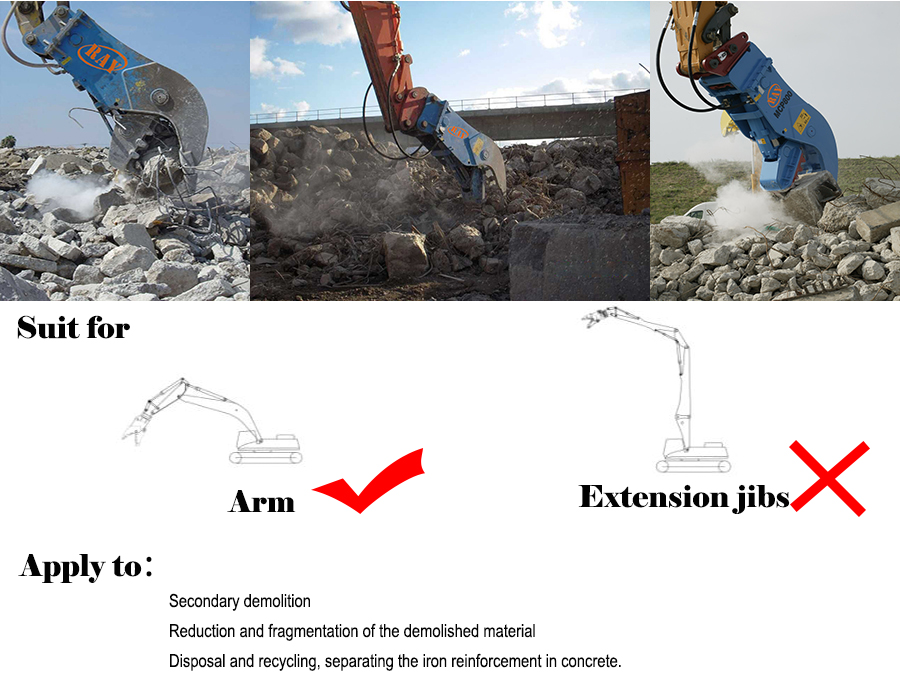

MCP fixed head pulveriser, with its new tooth design, is the ideal attachments for secondary demolition. The MCP is the perfect tool for crushing reinforced concrete and separating the rebar from the aggregate.

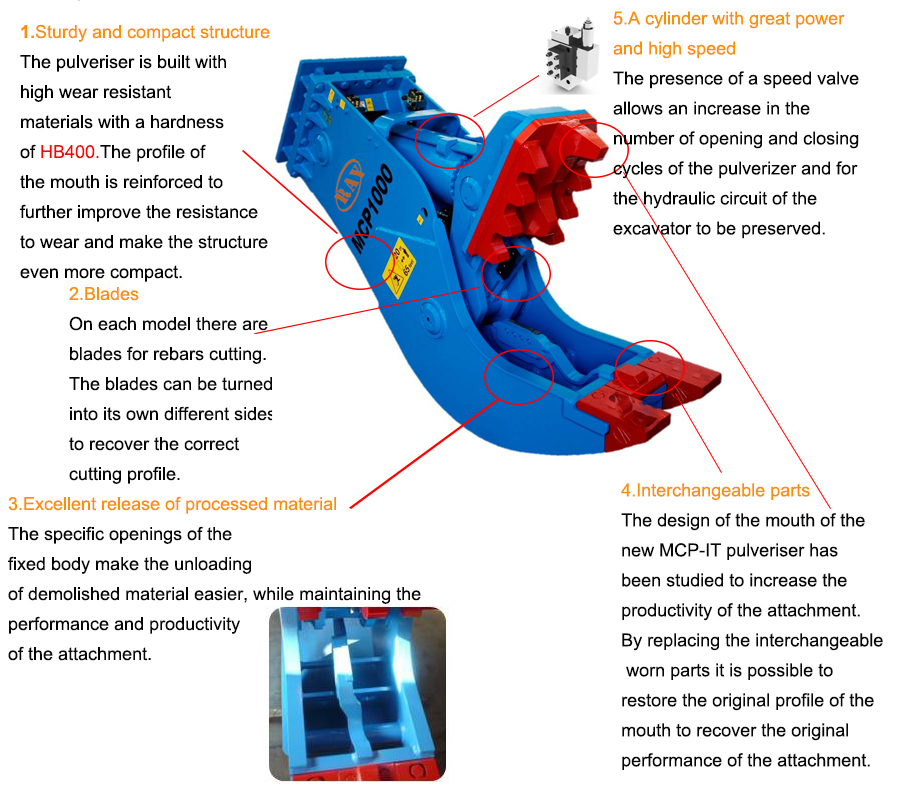

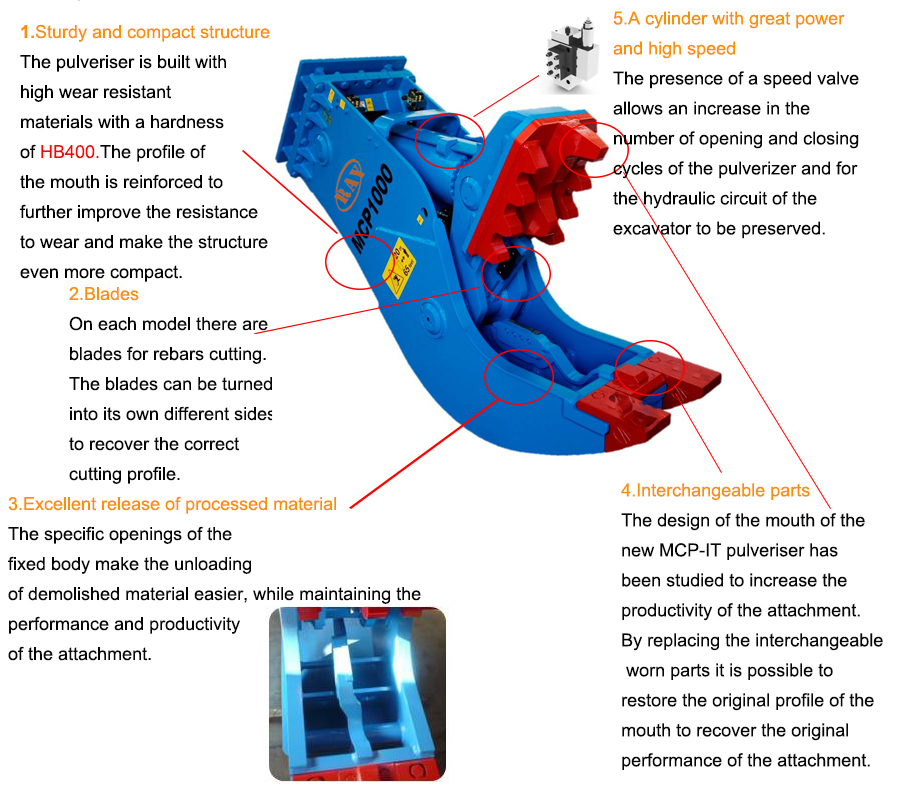

1.Sturdy and compact structure: The pulveriser is built with high wear resistant materials with a hardness of HB400.The profile of the mouth is reinforced to further improve the resistance to wear and make the structure

even more compact.

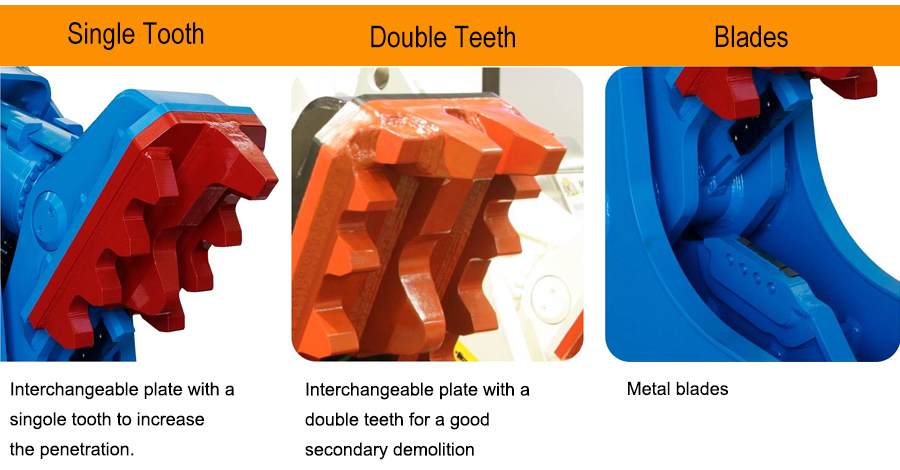

2.Blades: On each model there are blades for rebars cutting.The blades can be turned into its own different sides to recover the correct cutting profile.

3.Excellent release of processed material:The specific openings of the fixed body make the unloading of demolished material easier, while maintaining the performance and productivity of the attachment.

4.Interchangeable parts:The design of the mouth of the new MCP-IT pulveriser has been studied to increase the productivity of the attachment.By replacing the interchangeable worn parts it is possible to restore the original profile of the mouth to recover the original performance of the attachment.

5.A cylinder with great power and high speed:The presence of a speed valve allows an increase in the number of opening and closing cycles of the pulverizer and for the hydraulic circuit of the excavator to be preserved.

Tip 1: Make sure of the diameter and the cutting table of the object

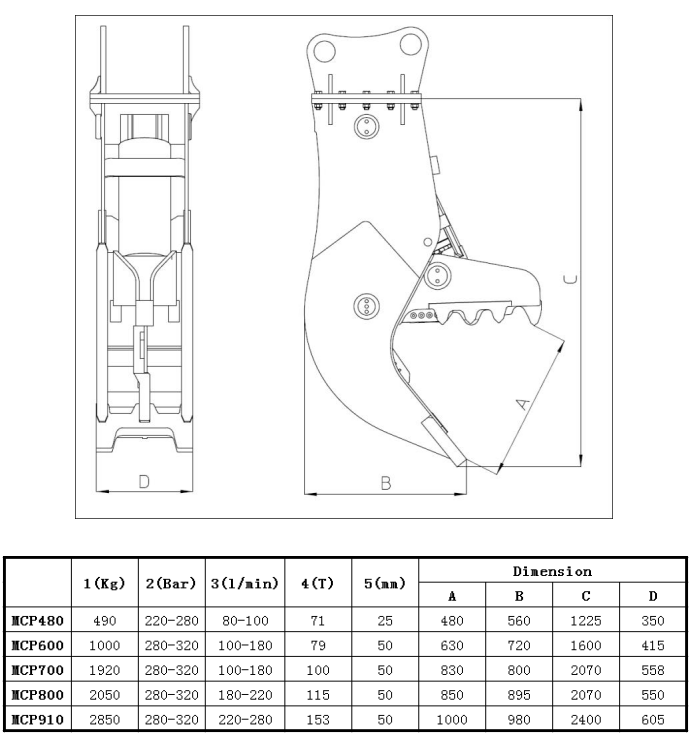

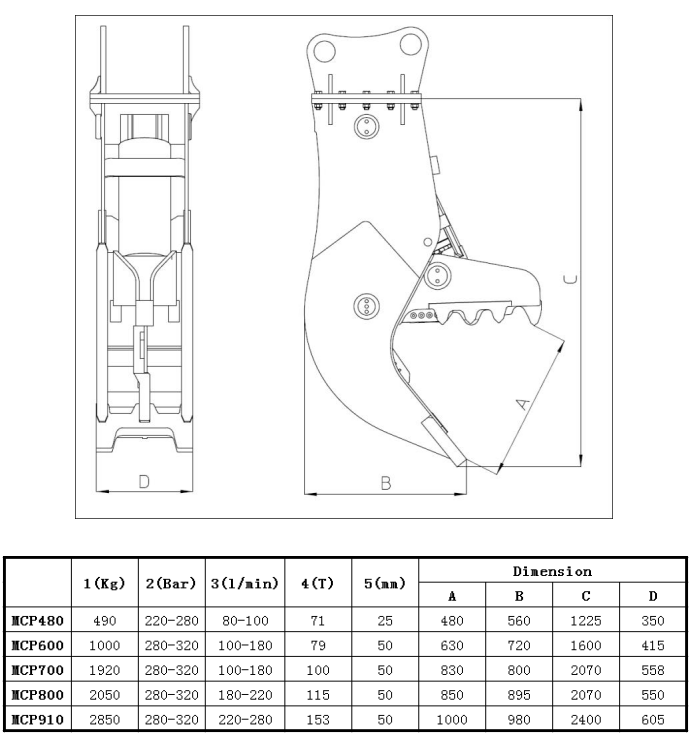

1) Weight

2) Working pressure

3) Oil flow

4) Force

5) Max Ø to be cut

| Model | Unit | MCP300 | MCP480 | MCP600 | MCP700 | MCP800 | MCP910 |

| Excavator weight | T | 1.5-4 | 4-10 | 10-18 | 16-22 | 18-25 | 25-35 |

| Tool weight | kG | 150 | 450 | 1000 | 1650 | 2050 | 2850 |

| Cylinder force | T | 24 | 71 | 100 | 120 | 145 | 157 |

| Rotation type | / | NO ROT. | NO ROT. | NO ROT. | NO ROT. | NO ROT. | NO ROT. |

| Speed valve | / | NO | NO | Optional | Yes | Yes | Yes |

| Max diameter to be cutted | mm | 15 | 25 | 50 | 50 | 55 | 60 |

| Jaw Opening | mm | 300 | 480 | 600 | 800 | 850 | 1000 |

| Blade length | mm | 80 | 120 | 122 | 200 | 180 | 180 |

| Automatic grease system | / | NO | NO | NO | NO | NO | NO |

MCP fixed head pulveriser, with its new tooth design, is the ideal attachments for secondary demolition. The MCP is the perfect tool for crushing reinforced concrete and separating the rebar from the aggregate.

1.Sturdy and compact structure: The pulveriser is built with high wear resistant materials with a hardness of HB400.The profile of the mouth is reinforced to further improve the resistance to wear and make the structure

even more compact.

2.Blades: On each model there are blades for rebars cutting.The blades can be turned into its own different sides to recover the correct cutting profile.

3.Excellent release of processed material:The specific openings of the fixed body make the unloading of demolished material easier, while maintaining the performance and productivity of the attachment.

4.Interchangeable parts:The design of the mouth of the new MCP-IT pulveriser has been studied to increase the productivity of the attachment.By replacing the interchangeable worn parts it is possible to restore the original profile of the mouth to recover the original performance of the attachment.

5.A cylinder with great power and high speed:The presence of a speed valve allows an increase in the number of opening and closing cycles of the pulverizer and for the hydraulic circuit of the excavator to be preserved.

Tip 1: Make sure of the diameter and the cutting table of the object

1) Weight

2) Working pressure

3) Oil flow

4) Force

5) Max Ø to be cut

| Model | Unit | MCP300 | MCP480 | MCP600 | MCP700 | MCP800 | MCP910 |

| Excavator weight | T | 1.5-4 | 4-10 | 10-18 | 16-22 | 18-25 | 25-35 |

| Tool weight | kG | 150 | 450 | 1000 | 1650 | 2050 | 2850 |

| Cylinder force | T | 24 | 71 | 100 | 120 | 145 | 157 |

| Rotation type | / | NO ROT. | NO ROT. | NO ROT. | NO ROT. | NO ROT. | NO ROT. |

| Speed valve | / | NO | NO | Optional | Yes | Yes | Yes |

| Max diameter to be cutted | mm | 15 | 25 | 50 | 50 | 55 | 60 |

| Jaw Opening | mm | 300 | 480 | 600 | 800 | 850 | 1000 |

| Blade length | mm | 80 | 120 | 122 | 200 | 180 | 180 |

| Automatic grease system | / | NO | NO | NO | NO | NO | NO |