SH410R

RAY ATTACHMENTS

| Availability: | |

|---|---|

Our eagle shear is manufactured from the highest grade steels, ensure the maximum tool strength, with the best possible wear resistance.

There are many customers satisfied with our hydraulic eagle shear for scrap steel. But they will also retreat as the high cost. The truth is the cost performance is high. We thought you are mainly worried the quality and the operation performance for the shear. Below are the points which can give your your confidence to own it.

1.1 Increased cylinder size for 20% more power.

1.2 Using Hengli hydraulic brand, Well-known manufacturer.

1.3 Forged cylinder rod for a better functionality and security.

2.1 The blades imported from Germany.

2.2 The front blade ensure accurate shearing with tip and can be turned.

2.3 The blades can be used repeatedly (rectangular, diamond).

2.4 The blades have been redesigned in a rhomboid shape to reduce stress on the jaws.

3.1 This allows for regular adjustment of the pin to ensure perfect shearing.

3.2 While fully protected the pin can be removed for maintenance of all related parts.

4.1 Bolted blades on piercing tip for fast replacement.

4.2 Eliminated time consuming rebuilding of the tip.

5.1 Reduced cycle times.

5.2 Regenerating power when required.

5.3 Protection for the shear eliminating pressure peaks.

| Steel structure | Rod | Tube | IPE | HEA | HEB | Plate | L profile | Rail |

| vignola | ||||||||

| unit | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| RSH25 | 40 | 114x4 | 120x55 | n.d | n.d | 6 | 100x10 | n.d |

| RSH130R | 50 | n.d | n.d | 100 | n.d | 8 | 120x10 | n.d |

| RSH130R | 55 | n.d | 200 | 120 | n.d | 10 | 120x10 | n.d |

| RSH180R | 60 | n.d | 270 | 140 | n.d | 12 | 120x12 | n.d |

| RSH310R | 70 | n.d | 300 | 200 | 450 | 18 | n.d | 36 |

| RSH410R | 90 | n.d | 450 | 320 | n.d | 20 | 200x24 | n.d |

| RSH550R | 100 | n.d | 500 | 360 | n.d | 22 | 220x24 | n.d |

| RSH700R | 120 | n.d | 600 | 400 | n.d | 25 | 240x24 | n.d |

| RSH900R | 150 | n.d | 900 | 600 | n.d | 35 | n.d | n.d |

| RSH25 | RSH50R | RSH130R | RSH180R | RSH310R | RSH410R | RSH550R | RSH700R | RSH900R | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

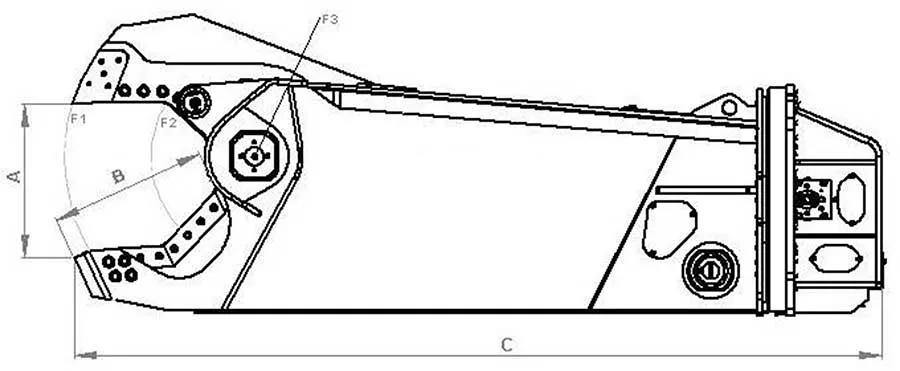

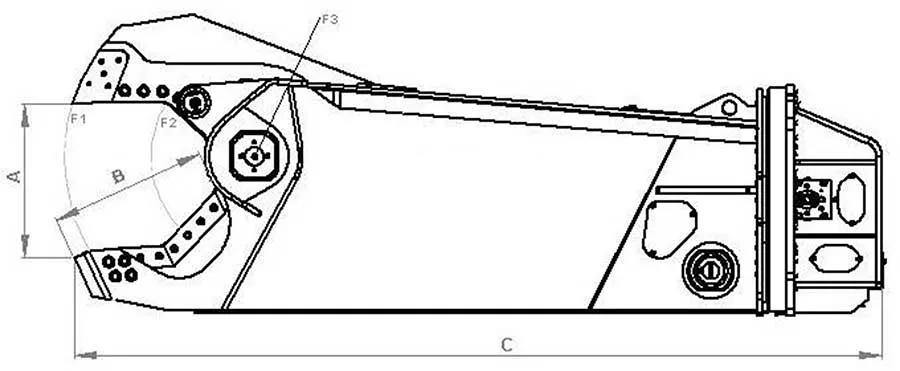

| Jaw opening A | 195 | 290 | 375 | 445 | 565 | 670 | 760 | 830 | 965 |

| Jaw depth B | 200 | 290 | 395 | 525 | 630 | 720 | 780 | 840 | 930 |

| Length C | 1350 | 1900 | 2100 | 2700 | 3300 | 3700 | 3950 | 4300 | 4600 |

Our eagle shear is manufactured from the highest grade steels, ensure the maximum tool strength, with the best possible wear resistance.

There are many customers satisfied with our hydraulic eagle shear for scrap steel. But they will also retreat as the high cost. The truth is the cost performance is high. We thought you are mainly worried the quality and the operation performance for the shear. Below are the points which can give your your confidence to own it.

1.1 Increased cylinder size for 20% more power.

1.2 Using Hengli hydraulic brand, Well-known manufacturer.

1.3 Forged cylinder rod for a better functionality and security.

2.1 The blades imported from Germany.

2.2 The front blade ensure accurate shearing with tip and can be turned.

2.3 The blades can be used repeatedly (rectangular, diamond).

2.4 The blades have been redesigned in a rhomboid shape to reduce stress on the jaws.

3.1 This allows for regular adjustment of the pin to ensure perfect shearing.

3.2 While fully protected the pin can be removed for maintenance of all related parts.

4.1 Bolted blades on piercing tip for fast replacement.

4.2 Eliminated time consuming rebuilding of the tip.

5.1 Reduced cycle times.

5.2 Regenerating power when required.

5.3 Protection for the shear eliminating pressure peaks.

| Steel structure | Rod | Tube | IPE | HEA | HEB | Plate | L profile | Rail |

| vignola | ||||||||

| unit | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| RSH25 | 40 | 114x4 | 120x55 | n.d | n.d | 6 | 100x10 | n.d |

| RSH130R | 50 | n.d | n.d | 100 | n.d | 8 | 120x10 | n.d |

| RSH130R | 55 | n.d | 200 | 120 | n.d | 10 | 120x10 | n.d |

| RSH180R | 60 | n.d | 270 | 140 | n.d | 12 | 120x12 | n.d |

| RSH310R | 70 | n.d | 300 | 200 | 450 | 18 | n.d | 36 |

| RSH410R | 90 | n.d | 450 | 320 | n.d | 20 | 200x24 | n.d |

| RSH550R | 100 | n.d | 500 | 360 | n.d | 22 | 220x24 | n.d |

| RSH700R | 120 | n.d | 600 | 400 | n.d | 25 | 240x24 | n.d |

| RSH900R | 150 | n.d | 900 | 600 | n.d | 35 | n.d | n.d |

| RSH25 | RSH50R | RSH130R | RSH180R | RSH310R | RSH410R | RSH550R | RSH700R | RSH900R | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| Jaw opening A | 195 | 290 | 375 | 445 | 565 | 670 | 760 | 830 | 965 |

| Jaw depth B | 200 | 290 | 395 | 525 | 630 | 720 | 780 | 840 | 930 |

| Length C | 1350 | 1900 | 2100 | 2700 | 3300 | 3700 | 3950 | 4300 | 4600 |